Base Material Selection

Alloy Systems:

| Series | Representative Grades | Core Characteristics | Typical Applications |

|---|---|---|---|

| 1XXX | 1060/1100 | Pure aluminum (≥99% Al), Excellent conductivity/thermal conductivity | Electronic foil, Packaging |

| 3XXX | 3003/3105 | Mg-reinforced, High corrosion resistance (salt mist > 2000h) | Curtain walls, Decorative panels |

| 5XXX | 5005/5705 | Mg-Si alloy, High tensile strength (≥270MPa) | Automotive structural parts |

| 6XXX | 6061/6063 | Al-Mg-Si heat-treatable alloy, Strength ≥310MPa | Aerospace components, High-end equipment |

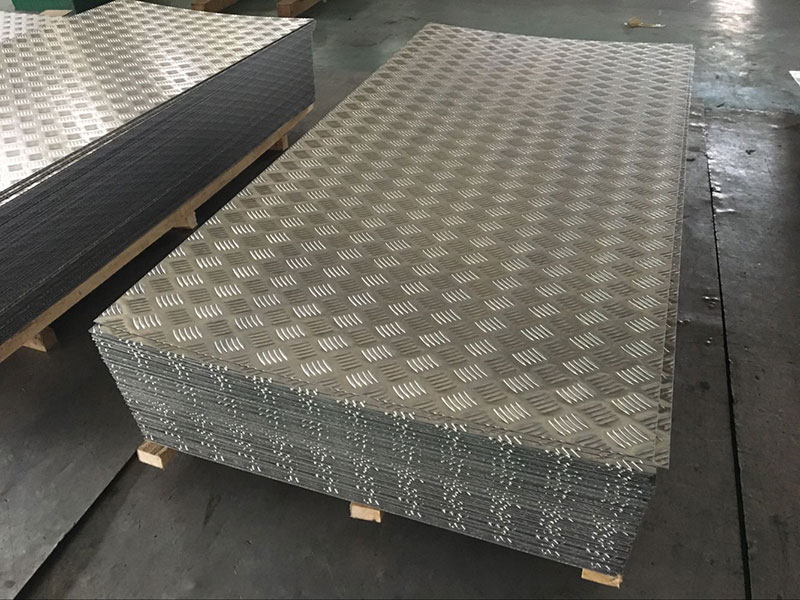

Cold-Rolling and Embossing Process

Mold types: Linear patterns (HRC 58–62), 3D patterns (Multi-stage pressing)

Residual stress: Surface compressive stress (50–100MPa), Suppress micro-crack propagation

Rolling temperature: 0–30°C (Avoid oxide layer thickening)

Reduction rate: ≥50% (Per pass reduction)

Surface roughness: Ra 0.8–3.2μm (Dependent on pattern depth)

Cold-Rolling Parameters:

Embossing Technology:

| Performance Indicator | Cold-Rolled Embossed Aluminum Plate | Traditional Coated Steel | Natural Wood |

|---|---|---|---|

| Density (g/cm³) | 2.7 | 7.8 | 0.6–0.9 |

| Bending Strength (MPa) | ≥150 | 120–180 | 30–80 |

| Weatherability (Years) | 30+ | 10–15 | 5–10 |

| Maintenance Cost | Low | Medium | High |

Architectural Curtain Walls

Use 3XXX-series alloys + fluorocarbon spraying (PVDF film thickness ≥40μm) to meet EN 13501-1 A2 fire rating.

Design guidelines: Minimum support spacing ≤2.5m, panel thickness ≥2mm.

Pain Points: Wind load resistance, weatherability, fire protection

Solution:

New Energy Vehicle Battery Packs

6061-T6 alloy + micro-arc oxidation ceramic film (Hardness HV 800), Weight reduction by 30%.

Surface copper plating (Thickness 50μm) for EMC shielding (CISPR 25 Class 5 compliance).

Pain Points: Lightweight, electromagnetic shielding, collision protection

Solution:

Precision Instrument Panels

5XXX-series alloys + hydrophobic coating (Contact angle >110°), Vibration attenuation rate >80%.

Surface resistance <1×10⁶Ω (ISO 18184 anti-static standard).

Pain Points: Vibration control, cleanliness, electrostatic protection

Solution:

Surface Functionalization

Nanopatterning: Superhydrophobic coatings (Contact angle >150°), Self-cleaning efficiency improved by 90%.

Laser Cladding: WC-Co hard alloy coating (Hardness >1800HV), Service life extended by 5x.

Green Manufacturing

Chromium-free Coloring: Pure water electrolysis technology (Wastewater reduction by 95%).

Closed-loop Recycling: Aluminum recovery rate >98% via thermal decomposition (600–700°C).

markdownStart → Application scenario (Construction/Automotive/Home Appliances) → Key performance requirements (Strength/Weatherability/Weight) → Alloy selection → Surface treatment → Mold customization → Sample verification

Conclusion

Cold-rolled embossed aluminum plate has become a core material in high-end manufacturing through synergism innovation of materials, processes, and surface technologies. Its technical trajectory continues to evolve toward high strength-lightweight (e.g., Al-Mg-Li alloys), ultra-long lifespan (>50 years weatherability), and multi-functional integration (EMI shielding + self-cleaning), driving product innovation in construction, transportation, and electronics sectors.

Note: This document may be supplemented with technical parameter tables, process flowcharts, and application case images for enhanced technical persuasion.