Aluminum Honeycomb Panel Technical Specification

General Use: Civil architecture, vehicle & ship decoration, and other industrial applications.

Technology Origin: Utilizes aerospace-grade material technology adapted for civilian sectors.

Full Automation: Modern factory production with precision thermoforming technology.

Thermal Management:

High thermal conductivity between aluminum skins and honeycomb core ensures synchronized thermal expansion/contraction of inner/outer layers.

Perforated honeycomb structure enables air circulation within the panel.

Structural Stability:

Slidable fastening system accommodates dimensional changes without deformation during thermal cycling.

| Component | Specifications |

|---|---|

| Panel Skin | - Top/Bottom: 3003H24 alloy aluminum (0.8–1.5mm thick) or |

5052AH14 high-manganese alloy aluminum (0.8–1.5mm thick) with: |

| | - Coating: PVDF fluorocarbon (UV/weather-resistant)

Paint: Color-resistant baked paint (superior scratch resistance, acid rain resistance, and self-cleaning vs. PVDF) |

| Backer | 0.6–1.0mm thick aluminum sheet |

| Total Thickness | 25mm (panel + core + backing) |

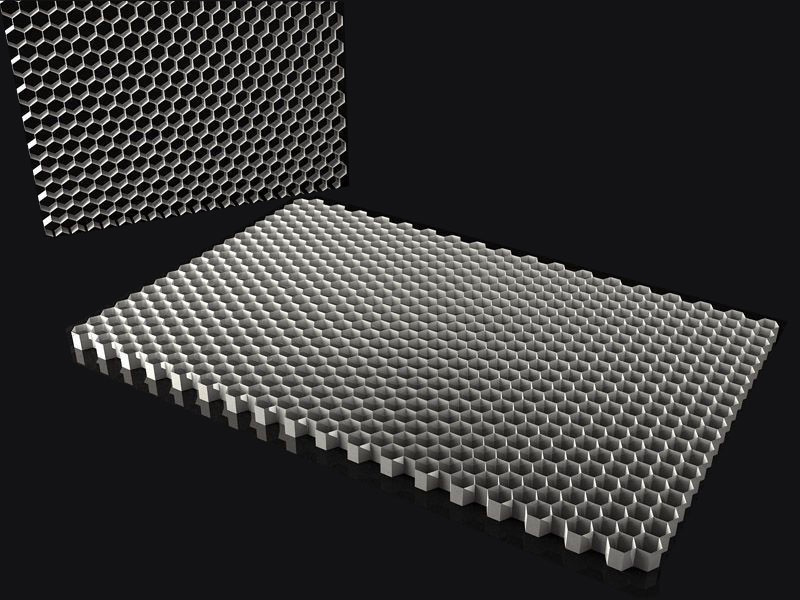

Structure:

Precision roller pressing for cell formation.

Fully automated edge folding for dimensional accuracy.

Tightly interlocked front/back skins for structural integrity.

Hexagonal 3003 aluminum honeycomb with cell side length 5–6mm and foil thickness 0.04–0.06mm.

Manufacturing:

Type: Two-component polyurethane high-temperature curing adhesive.

Application: Fully automatic composite equipment ensures no brittleness in bonding layers, enhancing long-term durability.

Core Performance:

Honeycomb core made of H19 hardness aluminum alloy for shear resistance in cross-sections.

Hexagonal cells function like miniature I-beams, distributing loads uniformly across large panel areas to ensure superior flatness.

Lightweight & High Strength:

Density is 1/5 of aluminum single panels and 1/10 of steel plates, achieving excellent strength-to-weight ratio.

Performance:

Outstanding resistance to wind pressure, vibration damping, sound insulation, thermal insulation, and fire retardancy.

Dimensional Stability:

Maintains high flatness even with large grid dimensions (up to 15mm total thickness).

Applications:

Widely used in high-rise building facades due to durability and dimensional stability.